Plastic production is among the most essential and rapidly increasing businesses throughout the world, as the business and customer consumption of plastic consistently improve. To meet this desire, producers are continually seeking for successful and price-efficient ways to make higher-top quality plastics. 1 process that has received consideration recently is Rotational Molding, that provides a unique pair of advantages, such as overall flexibility, toughness, and price-performance. Within this post, we are going to explore the ability of Rotomolding and just how it can be revolutionizing plastic manufacturing.

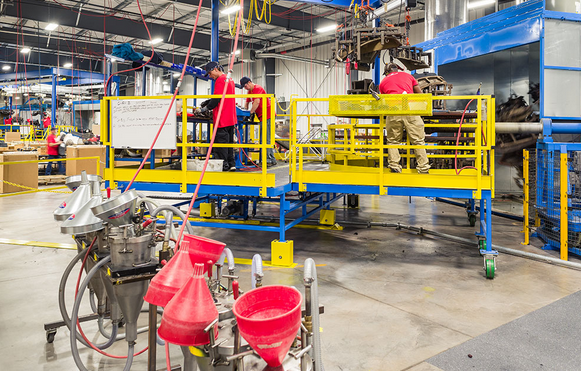

Rotomolding, also referred to as rotational molding or rotocasting, is really a manufacturing process that involves heating and air conditioning plastic-type resin in the mold, causing hollow plastic material pieces. The method employs a rotationally moldedmold that rotates around two perpendicular axes inside an your oven. In the course of manufacturing, powder resin is poured in to the mold, which is in contact with great temperature ranges, therefore melting the resin and finish the interior. The mold is going to be shifted in to the air conditioning chamber, where the plastic cools down and stabilizes, causing a done plastic item.

The Rotomolding process provides a selection of special benefits in comparison with other plastic-type material manufacturing techniques. Very first, it allows for highly intricate style and shapes that other production strategies cannot complete. This adaptability is simply because resin can be channeled in the fungus by means of a number of relationship details, contributing to highly complex styles. Second, the method produces hollow, monolithic parts which are light in weight yet extremely resilient. Consequently, rotomolded merchandise are ideal for a selection of apps, from children’s games and leisurely devices to fuel tanks and enormous containers.

Rotomolding can be a highly reliable developing process, and the final items can beeasily personalized in line with the client’s features. This mobility provides for the production of goods from numerous supplies, which include polyethylene, nylon material, Acrylonitrile Butadiene Styrene (ABS), and polyvinyl chloride (Pvc material). The ultimate products are typically simple to keep and inexpensive, making them broadly readily available and helpful to businesses of all shapes and sizes.

short

The art of Rotomolding has indeed revolutionized plastic material manufacturing. Having its special advantages, it is now a widely adopted generation strategy across many sectors. It offers exceptional versatility, durability, and price-usefulness, rendering it the go-to means for developing a large choice of potential plastic material items and parts. So, if you are an industrialist or possibly a customer, let’s embrace the skill of Rotomolding, as the mobility and productivity pros consistently revolutionize plastic material manufacturing.